A Tier 1 Australian coal mine was experiencing regular excavator pin and bush failures, costing up to $10 million AUD in downtime plus significant repair costs, due to a lack of visibility into actual grease application. GreaseBoss’s Critical Point Monitoring system provided this crucial data, quickly identifying issues like bypassing injectors and incorrect grease volumes, enabling early intervention.

- Prevent catastrophic excavator pin and bush failures and associated multi-million dollar downtime losses.

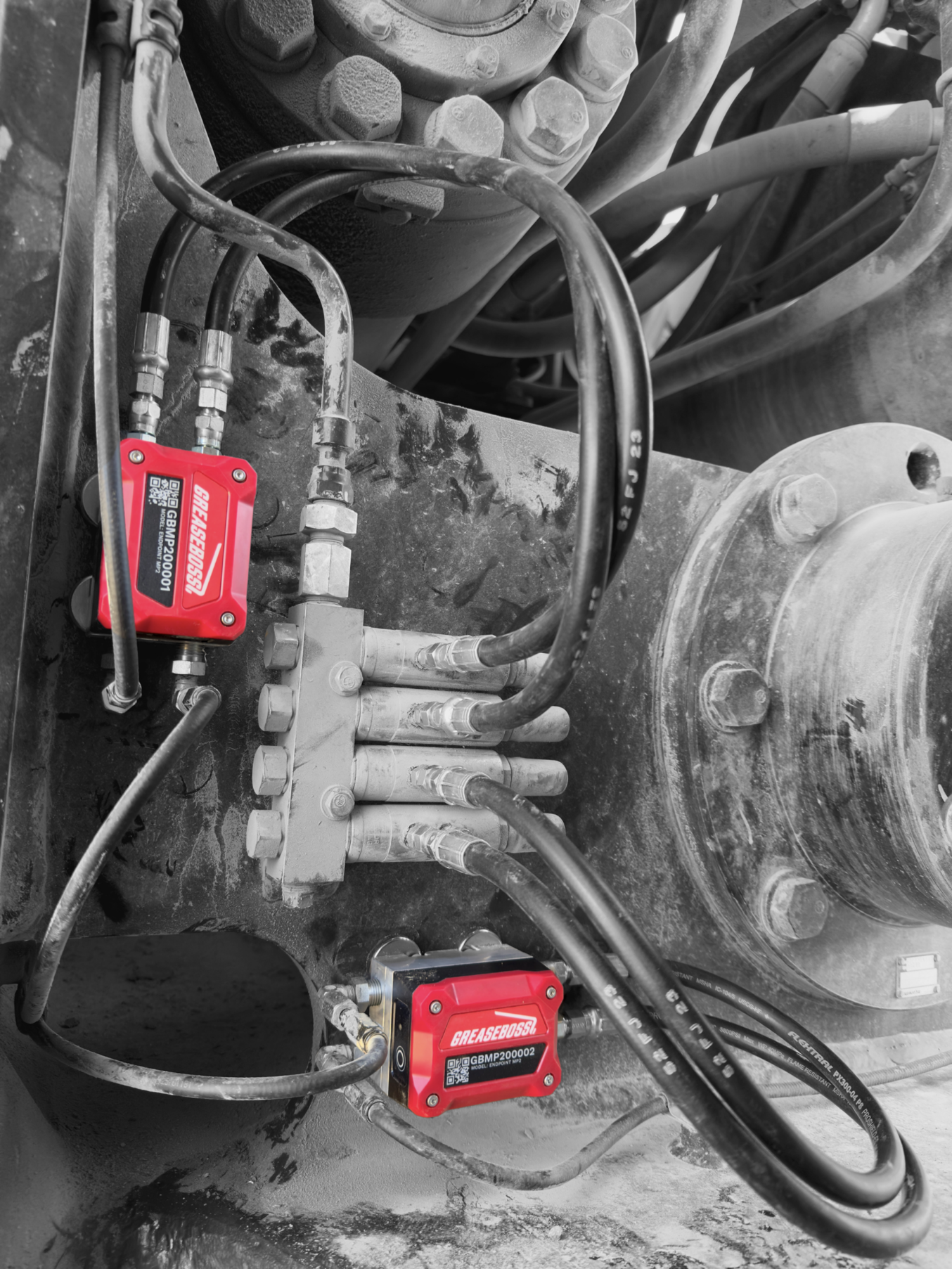

- Gain essential visibility into actual grease volumes delivered to critical excavator lubrication points.

- Identify lubrication system anomalies and injector faults far earlier than standard equipment monitoring allows.

- Reduce expensive repair costs and minimise equipment downtime through proactive, data-driven maintenance.