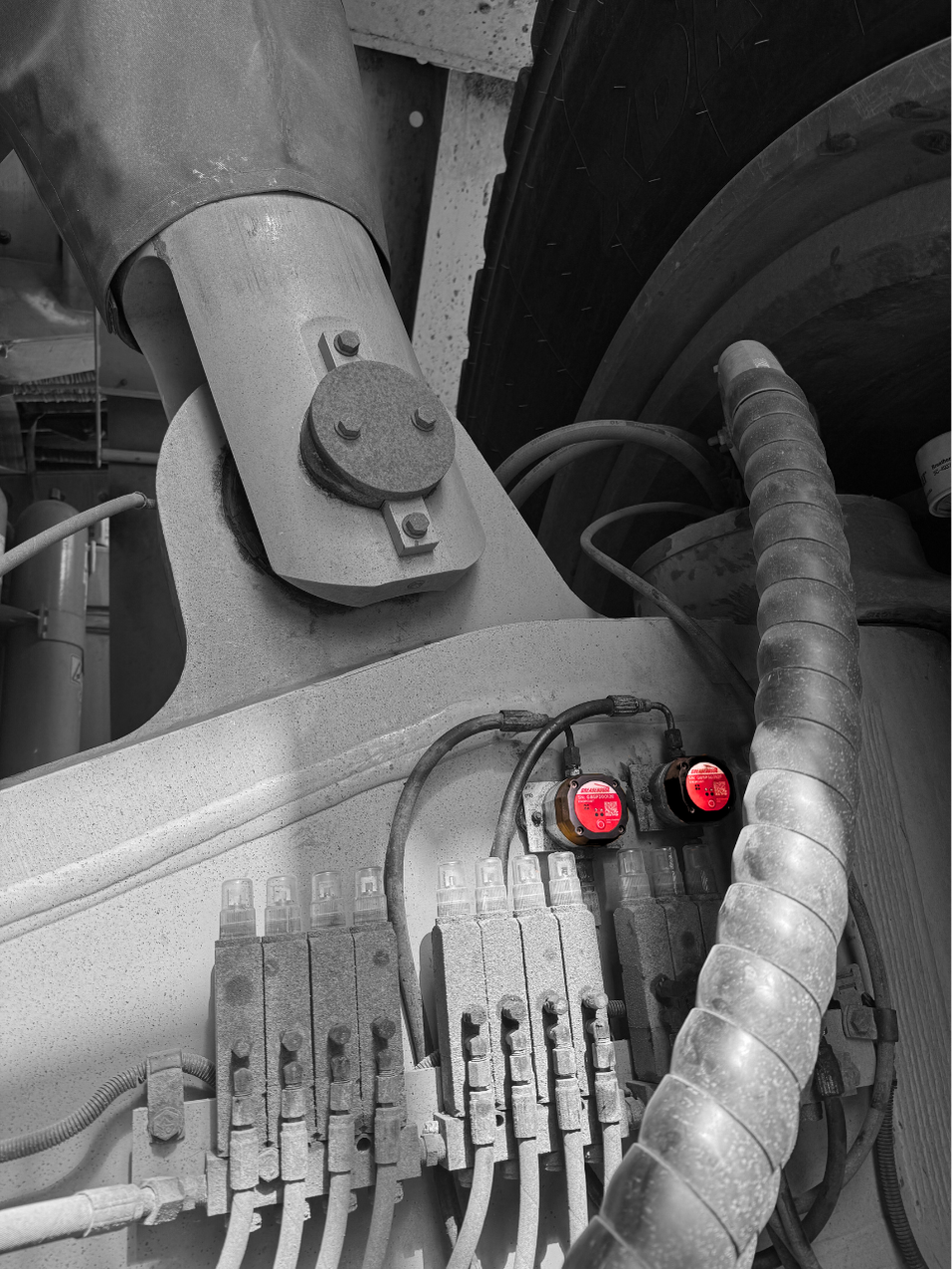

This pilot saved our client around $6,000,000 a year. The GreaseBoss system immediately identified severe under-greasing across all monitored injectors, allowing targeted maintenance and significantly improved truck performance.

- Immediate identification of injector issues – all four injectors were severely under-greasing these critical components.

- Reveal root cause of greasing issue – many injectors were mistuned.

- Detected autolubricator system failure – this finding triggered a full fleet refit.