GreaseBoss’s monitoring system identified insufficient lubrication and systemic autolube configuration errors as root causes, saving our client around $6.5 million annually.

- Eliminate frequent and costly haul truck kingpin failures, saving $250k-$500k per event.

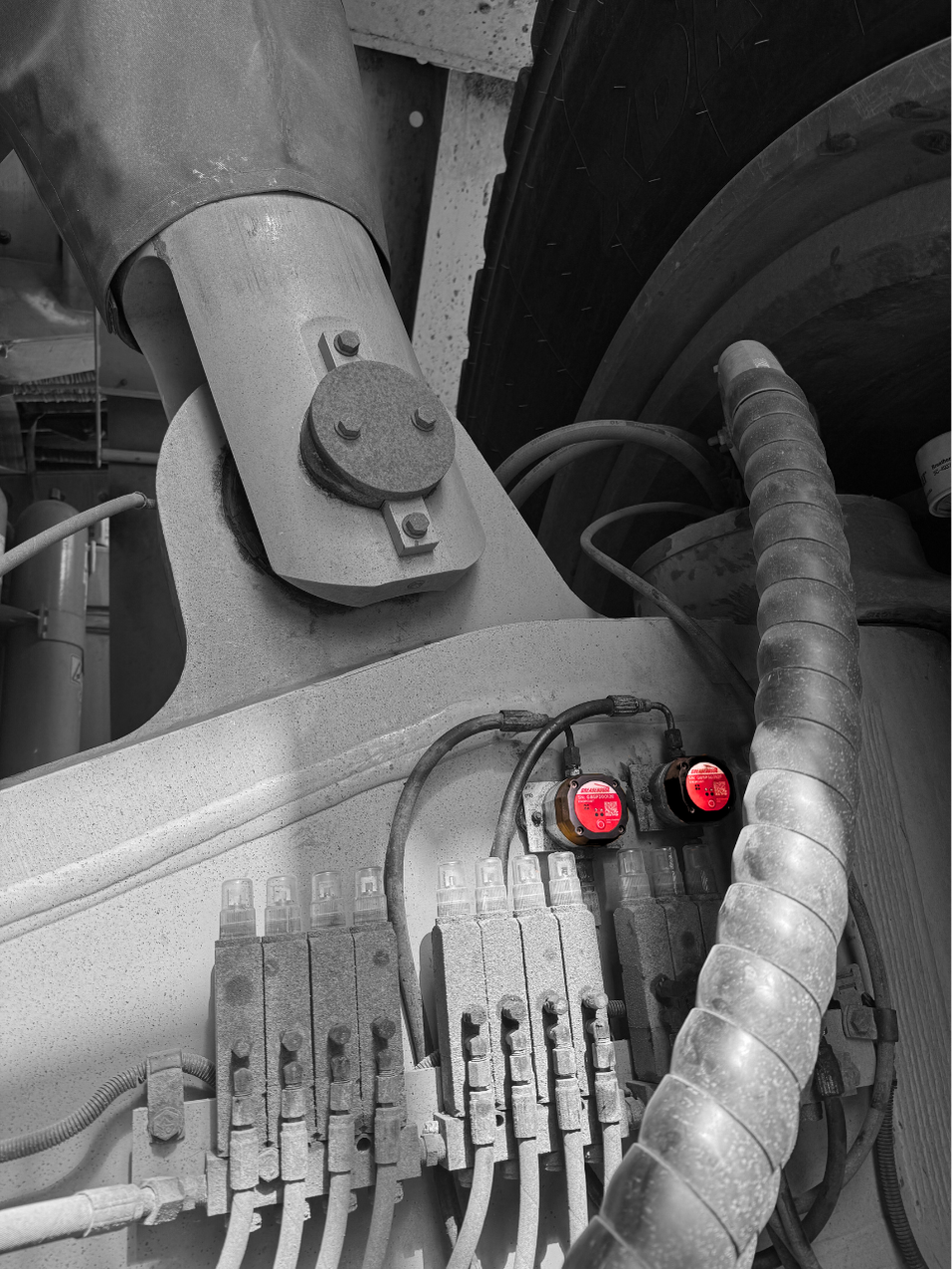

- Identify the root cause of lubrication issues, including insufficient grease delivery and faulty/mistuned injectors.

- Detect critical fleet-wide system configuration errors missed by standard checks.

- Achieve significant forecasted annual savings ($6.5 million) by preventing lubrication-related failures.