GREASEBOSS PRODUCTS.

data driven. dirt-ready

Discover our products, all designed and built to be:

Simple. Intuitive. Robust. reliable.

PRODUCT

Endpoint MP2

The Endpoint MP2 is a first-in-class device that guarantees precise grease flow to critical points, detects hose and line breakages, and monitors injector conditions in heavy mobile equipment with injector-based lubrication systems. The data is synced to a nearby Gateway, via Bluetooth.

This ensures lubrication systems are delivering the right amount of grease to each injection point, preventing grease-related asset failures and optimising maintenance processes.

PRODUCT

Endpoint BF

Endpoint Bulk Flow (BF) is a high-capacity monitoring device designed to track lube pump performance and grease tank filling. It measures directional flow during both pressurisation and venting, capturing how much grease enters the system and how much returns via the dump valve. This delivers visibility into auto lube pump function, full-system performance and remote grease tank fill level monitoring on critical assets.

PRODUCT

Endpoint LF/HF

Endpoint LF (low flow) and HF (high flow) are rugged, wireless, battery-powered flow meters that accurately measure grease volume in automatic lubrication systems. The Endpoint LF models install downstream of injectors and distributors to monitor critical points, while the Endpoint HF model is designed for trunk line monitoring for less critical/more cost-effective injector bank monitoring and for use in high-viscosity fluids like open gear lubricants.

PRODUCT

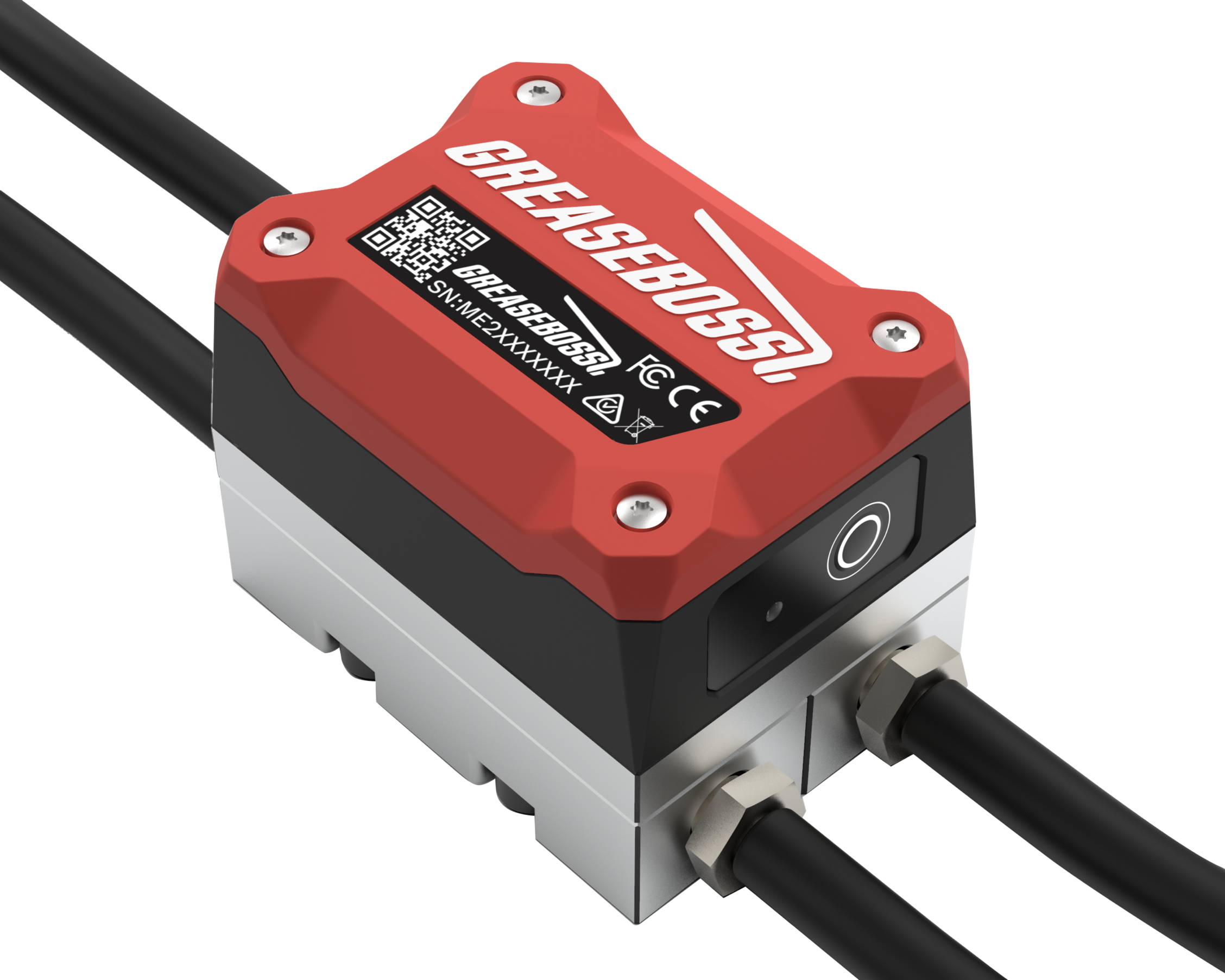

HME Gateway

The HME Gateway is a robust and versatile solution designed to enhance connectivity and data transmission in harsh operational environments. It supports multiple backhaul options like 4G/LTE SIM, Wi-Fi, and OT network integration, ensuring reliable performance.

PRODUCT

GreaseTags

The GreaseTags are robust RFID tags made from engineering plastic with a ceramic RFID chip, designed for industrial use. With an IP68 rating, exceptional chemical and UV resistance, GreaseTags ensure reliable and accurate tracking in the harshest conditions.

PRODUCT

Head Unit

The Head Unit retrofits to any grease gun, putting live lubrication schedules and step-by-step instructions directly in the hands of greasers. It guides them through each lube route, captures greasing data in real time, and syncs it to the GreaseBoss Cloud via the Gateway for analysis and reporting.

PRODUCT

Gateway

Versatile and wide reaching, the GreaseBoss Gateway provides ultimate flexibility in data backhaul to the GreaseBoss Cloud. Connectivity options include: 4G LTE SIM, site Wifi or ethernet. No matter where your operations are located, you can maintain a reliable and consistent connection to the GreaseBoss Cloud.