greaseboss products

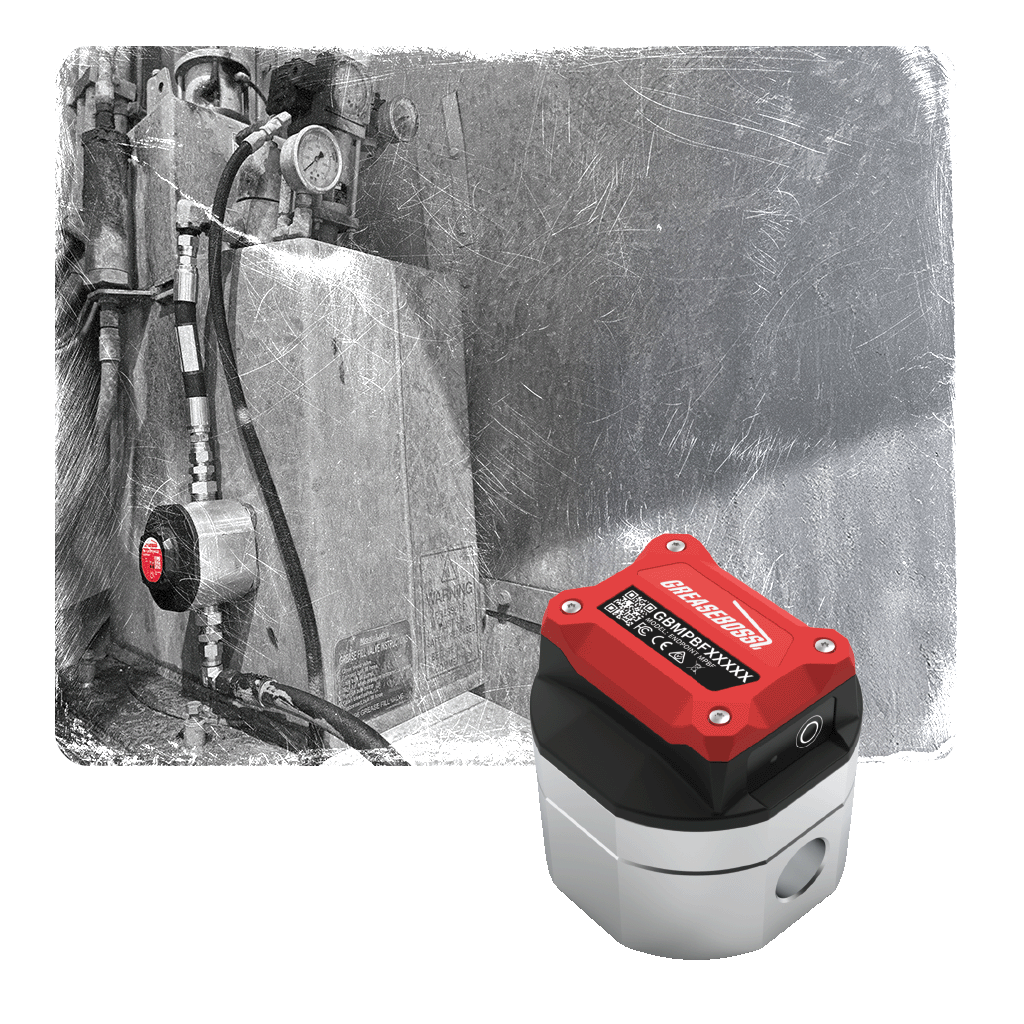

Endpoint BF

The Endpoint BF (Bulk Flow) are scaled up Endpoints, designed to monitor lube pump performance and grease tank filling. Capable of handling high flow rates, the Endpoint BF can also measure directional flow, recording how much grease is pumped into a lube system during pressurisation as well as how much grease flows back through the dump valve into the grease tank during system venting. This visibility provides world leading auto lube pump and holistic system monitoring for critical assets.

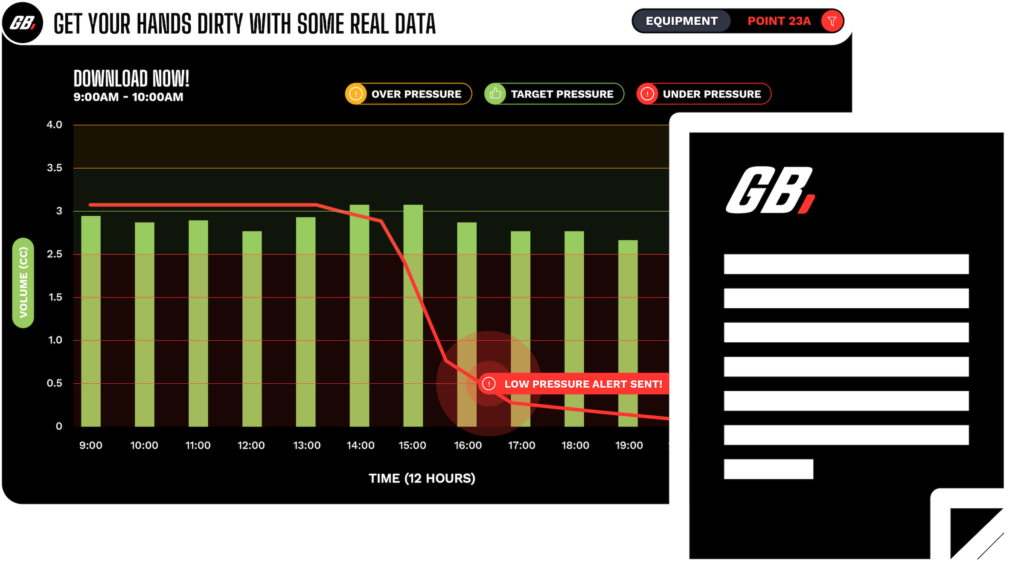

DOWNLOAD

SPECIFICATIONS

GreaseBoss endpoint bf

how it works

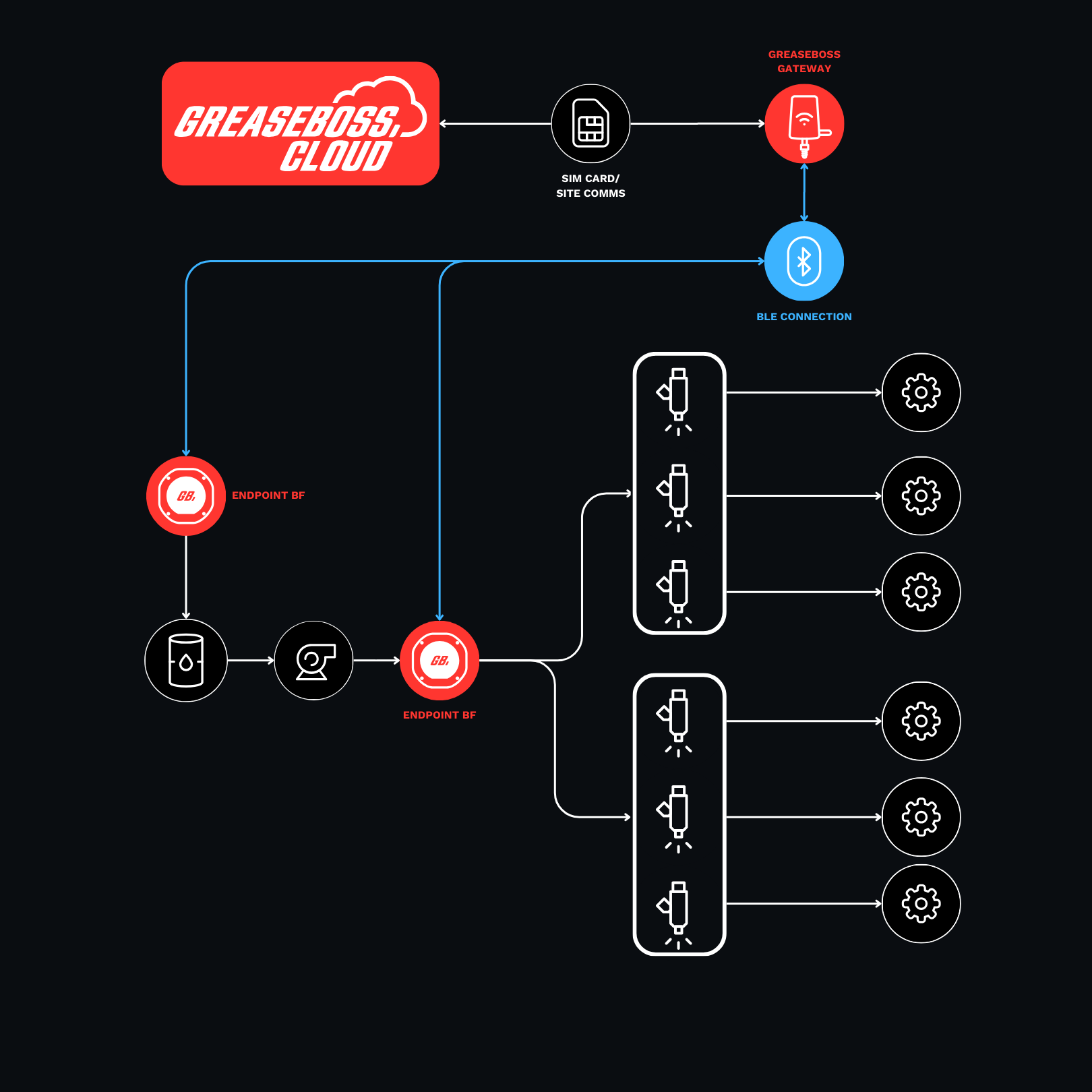

The Endpoint BF units record the exact volume of grease that passes through them when the tank is filled or the automatic lubrication pump fires. As the Endpoint BF units are directional, they also measure the volume of “backflow” that flows back into the grease tank when the auto lube system depressurises. This flow data is periodically synced (typically every hour) to the nearby Gateway, via Bluetooth.

The Gateway syncs with all Endpoints in the vicinity (typical range is between 50m – 250m, depending on the environment). This Endpoint data is synced to the GreaseBoss Cloud via the configured network backhaul (typically 4G/LTE SIM, site Wi-Fi or site OT network).

For remote grease tank fill level monitoring, the Endpoint BF units are configured in the GreaseBoss Cloud to either fill or empty a “reservoir”. This measurement of volumetric flow in and out of grease tanks provides a very reliable and accurate grease tank level measurement.

To monitor grease pump performance, the Greaseboss Cloud also compares the planned vs actual grease volumes and triggers automatic alerts to maintenance teams if there is an issue with the automatic lubrication system.

got questions?

see our faqs

No FAQs found.