greaseboss products

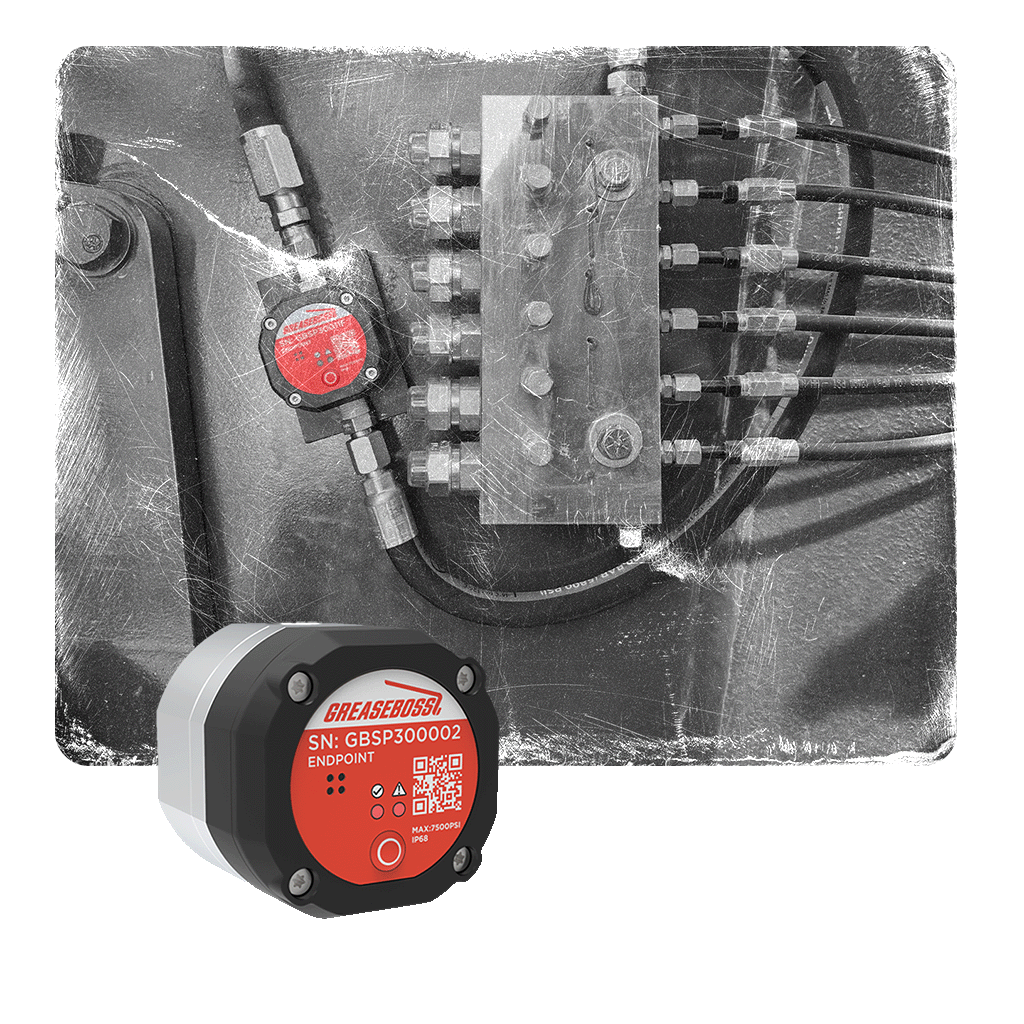

Endpoint LF/HF

The Endpoint Low Flow (LF) and High Flow (HF) products are robust, wireless, battery operated and accurate industrial flow meters that record the exact volume of grease delivered through auto lube systems. Endpoint LF units are installed downstream of injectors and distributors while Endpoint HF units are installed on automatic lube system trunk lines or systems with high viscosity fluids (such as open gear lubes).

DOWNLOAD

SPECIFICATIONS

GreaseBoss Endpoint LF/HF

how it works

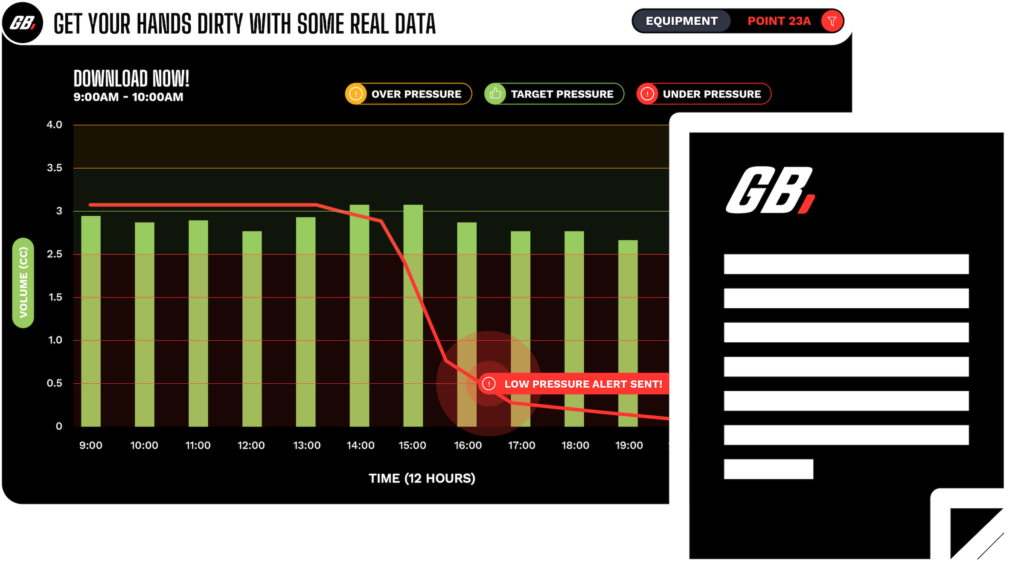

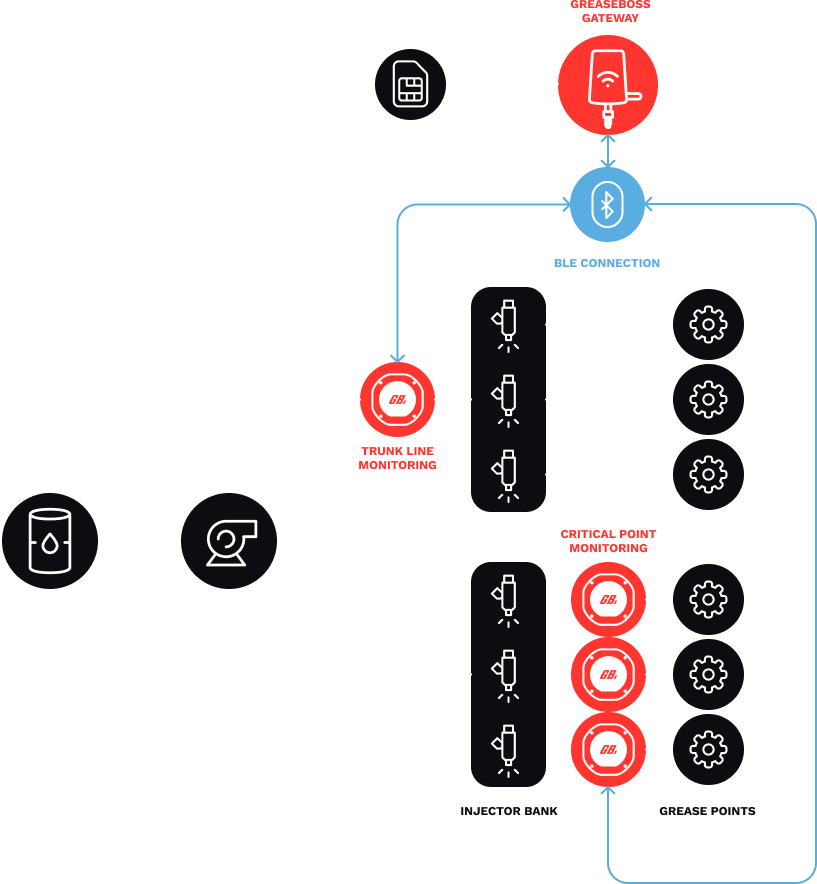

The Endpoints record the exact volume of grease that passes through them when the automatic lubrication pump fires. This data is periodically synced (typically every hour) to the nearby Gateway, via Bluetooth.

The Gateway syncs with all Endpoints in the vicinity (typical range is between 50m – 250m, depending on the environment). This Endpoint data is synced to the GreaseBoss Cloud via the configured network backhaul (typically 4G/LTE SIM, site Wi-Fi or site OT network).

The Greaseboss Cloud compares the planned vs actual greasing and triggers automatic alerts to maintenance teams if there is an issue with the automatic lubrication system.

got questions?

see our faqs

Our operations are remote. If no access to 4G system are there alternative communication options?

Yes. The Gateway can be configured to use site WI-FI network or connected via LAN directly into the site OT network where the data is processed on an on-site server then forwarded to the GreaseBoss Cloud.

The GreaseBoss team will work with our customers to set up the most suitable backhaul option for client’s requirements.

How does my grease event data get to the GreaseBoss Cloud?

The data is synced from the devices to the Gateway via Bluetooth. The Gateway then forwards data to the GreaseBoss Cloud using the configured connectivity backhaul option.

Can I use my site wi-fi to connect to the GreaseBoss Cloud?

Yes, the GreaseBoss team will work with your site IT/OT team to use existing WI-FI networks to connect to the GreaseBoss Cloud.

Can I install or do I need a qualified GreaseBoss installer?

The system can be easily installed by customers with remote support from the GreaseBoss team but we do offer installation services directly with our Certified GreaseBoss installers to provide high–quality turnkey solutions to our customers.

What training and onboarding do I get from GreaseBoss?

The GreaseBoss onboarding process is comprehensive and assists to set up the correct lubrication data in the GreaseBoss Cloud, and to prepare the site for installation, commissioning, and on-going operations.

GreaseBoss offers comprehensive training to customer teams in the field for installation, commissioning and hardware use, training for the office team on how to use the GreaseBoss Cloud, and how to interpret the reports & alerts.