Solution Type: Mobile

-

Komatsu Case Study

“The visibility of lubrication allows us to not only meet the operating targets, but extend the…

-

Glencore mangoola – SYSTEMISE MANUAL GREASING TO BOOST RELIABILITY

The Mangoola team use external contractors to perform manual lubrication tasks and needed visibility and assurance…

-

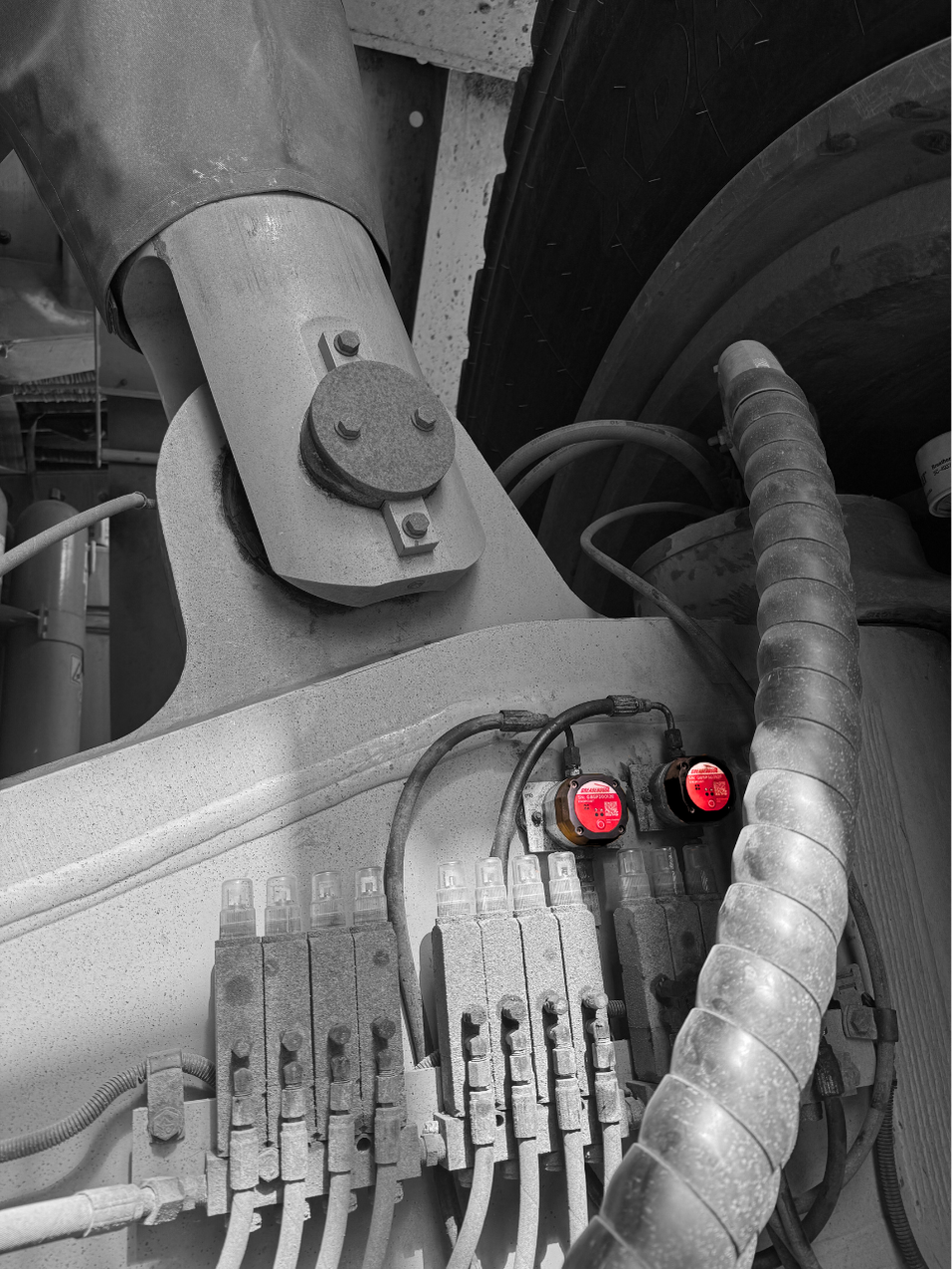

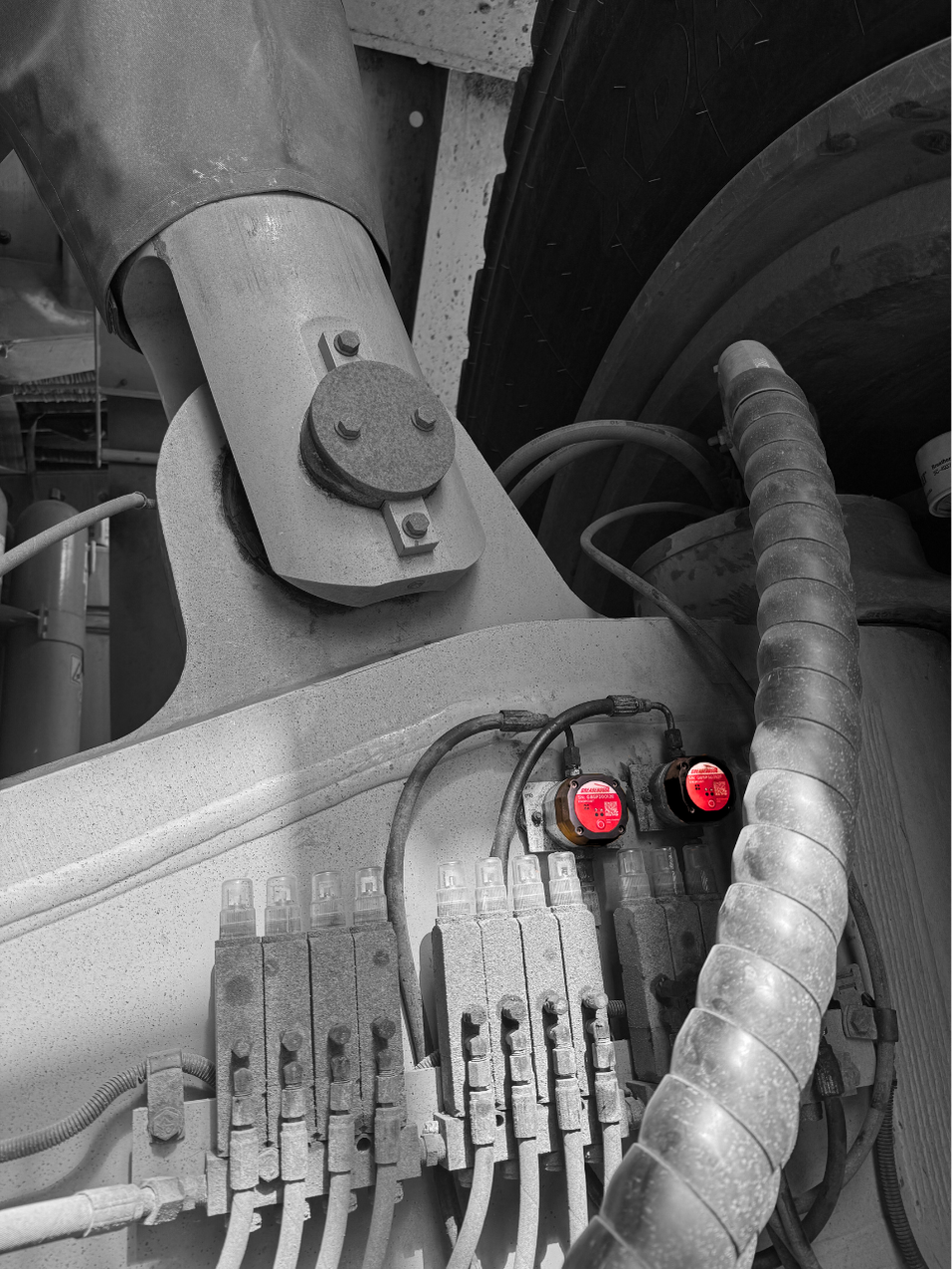

EXCAVATOR HOIST CYLINDER AND BUCKET PIN MONITORING – KOMATSU PC7000

By installing Endpoint MP2s, the GreaseBoss system immediately identified a critical issue with the lube system…

-

HAUL TRUCK – CAT 796AC KINGPINS

This pilot saved our client around $6,000,000 a year. The GreaseBoss system immediately identified severe under-greasing…

-

HAUL TRUCK A-FRAME & Pump Monitoring

The customer experienced systemic A-frame bearing failures on their entire haul truck fleet. Without GreaseBoss, both…

-

Solving Haul Truck Kingpin Failures: $6.5M Annual Savings with GreaseBoss Monitoring

GreaseBoss’s monitoring system identified insufficient lubrication and systemic autolube configuration errors as root causes, saving our…

-

Critical Point Monitoring

the value of cpm key benefits Ensure critical pins and bushes receive the correct grease volume…

-

Bulk Lubrication Management

the value of BLM key benefits Monitor automatic lubricator system health Verify every pump cycle Ensure…