fixed plant solutions

Take control of your plant’s lubrication and reliability

Empower your maintenance team with visibility over planned vs actual greasing across your entire plant. Lubrication is too important to leave to chance. Systemise your plant’s lubrication, enable workers with basic training to grease perfectly and monitor automatic lubrication systems to ensure they are delivering the correct grease volumes.

FIXED PLANT SOLUTIONS VIDEO

full plant coverage

Automatic and manual greasing – we’ve got you covered

Fixed plant solutions

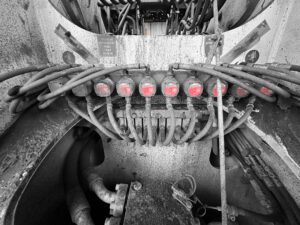

Critical Point Monitoring

Verify automatic Lubricators Are Delivering the Correct Volume

Automatic lubrication systems are perfect for greasing critical equipment. However, they have multiple failure points, many of which can fail without being noticed. One failed injector can impact the entire lube system’s performance, without triggering traditional automatic lubrication system alarms.

Critical assets require close monitoring. Our Critical Point Monitoring solution verifies the exact volume of grease delivered to each monitored grease point every pump cycle. Powerful reporting provides insights into lube system health and alerting notifies maintenance team as soon as grease delivery is out of specification. This enables maintenance teams to fix automatic lubrication systems instead of fixing critical equipment failures.

Fixed plant solutions

Manual Lubrication Management

Enable Anyone to Grease the Plant Perfectly

GreaseBoss’ Manual Lubrication System transforms maintenance operations by providing managers with clear visibility over planned versus actual greasing activities, eliminating the need for paperwork in lubrication work orders. This system empowers workers with basic training to perform greasing tasks accurately, reducing business exposure to high staff turnover.

With historical grease recordkeeping for OEM warranty claims and optimised grease routes, our solution ensures preventative maintenance schedules are adhered to, safeguarding your equipment’s operational integrity and enhancing overall efficiency.